Product details

In the construction of modern complex pipeline systems, PE pipe reducing tees serve as core hubs for connecting and diverting pipes of different diameters. They play a crucial role in ensuring the precise transportation of fluids and optimizing pipeline network layouts. As a leading PE pipe manufacturer in China, Hubei Gongyuan Building Materials Co., Ltd., relying on more than two decades of technical accumulation and innovative practices, meticulously crafts high-performance PE pipe reducing tees for global customers, empowering various engineering projects to be efficiently implemented with superior quality.

The PE pipe reducing tees produced by Hubei Gongyuan Building Materials are made from carefully selected high-quality virgin polyethylene raw materials and manufactured using cutting-edge multi-layer co-extrusion and precision injection molding processes. The entire production process strictly adheres to international standards and Chinese national standards. Digital inspection equipment is used to conduct real-time monitoring of 18 core indicators, including pipe diameter tolerance and wall thickness uniformity. This ensures that the dimensional accuracy error of the products is less than ±0.3mm, enabling seamless connection with pipes of different diameters. The unique streamlined reducing structure design reduces the pressure loss during fluid diversion by 40%. These tees are widely applied in scenarios such as municipal rain and sewage diversion, industrial circulating water systems, and gas pressure regulating stations.

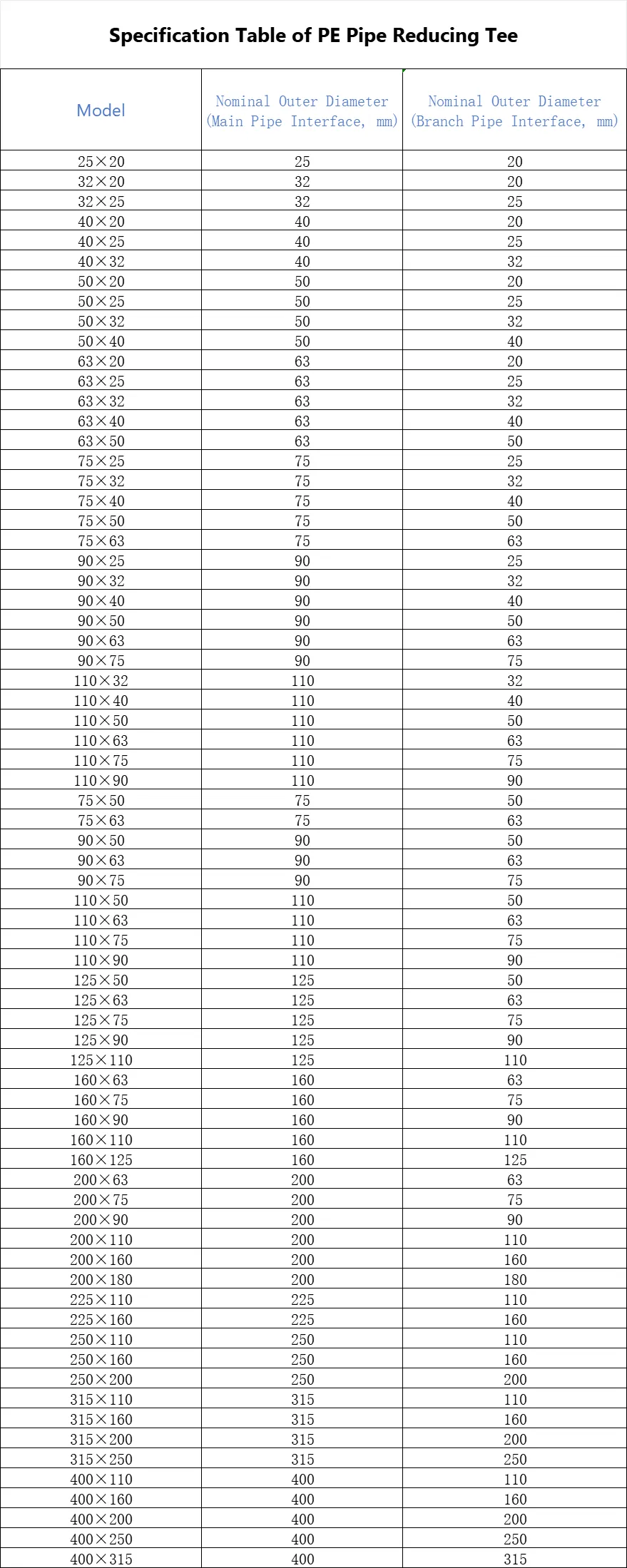

The product has multiple core competitive advantages. In terms of environmental resistance, the molecular structure of polyethylene endows it with excellent corrosion resistance. It can operate stably for more than 50 years in acidic and alkaline environments with a pH value ranging from 3 to 11, far surpassing traditional metal pipe fittings. Regarding pressure-bearing performance, the product has been verified through a 1.5-fold hydrostatic burst test and can withstand continuous working pressures ranging from 0.8MPa to 1.6MPa, ensuring zero leakage in branch pipelines. The company offers a full range of standard specifications from DN25 to DN1200 and supports customized reducing tees to meet the diverse needs of global customers.

As a benchmark enterprise in China's PE pipe industry, Hubei Gongyuan Building Materials owns intelligent production bases and multiple automated production lines. From raw material inspection upon arrival at the factory to stringent quality inspection procedures for finished products, a full-process quality control system has been established. Relying on a global logistics network and local technical service teams, through diverse transportation solutions such as the China-Europe Railway Express and ocean containers, the company can achieve delivery within 45 days to major markets in North America, Europe, Southeast Asia, etc., and provides 24-hour online technical support. Choosing the PE pipe reducing tees from Hubei Gongyuan Building Materials means choosing a Made-in-China solution that integrates reliability, efficiency, and global services.