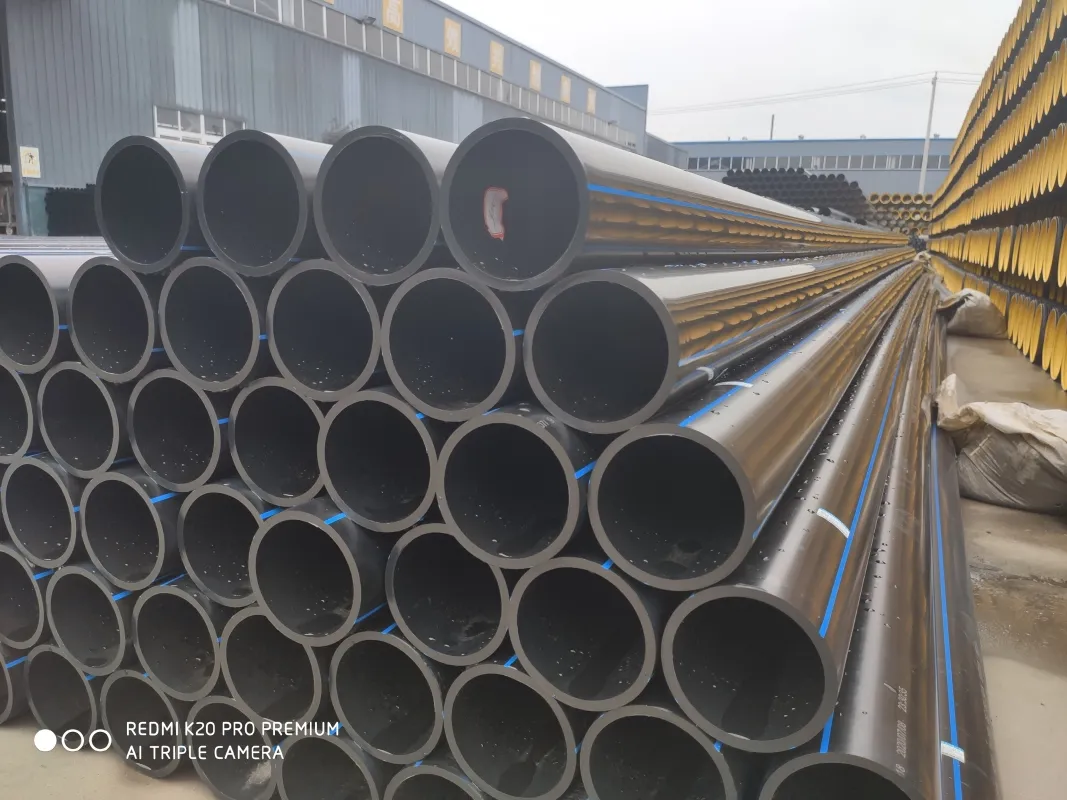

PE pipe as a commonly used pipe material, its connection is very important. Chinese PE pipe manufacturers in the long-term production and practice, the formation of a variety of mature connection methods, Hubei AD Building Materials Co., Ltd. as a professional PE pipe manufacturers, to provide users with reliable connection solutions.

1, hot melt connection: can be divided into hot melt butt and hot melt socket. Hot melt butt is suitable for large diameter PE pipe, through the hot melt butt machine to heat the ends of the pipe to the molten state, and then quickly butt, so that the two closely combined, this way of high strength, good sealing. The hot melt socket is suitable for small diameter PE pipe, using the hot melt characteristics of the socket and the pipe, the pipe is inserted into the socket to achieve a firm connection, which is easy to operate and efficient.

2, Electrofusion connection: It is completed by means of electrofusion pipe fittings. There are heating elements inside the electrofusion pipe fittings. After inserting the PE pipe into the electrofusion pipe fittings, the contact surface between the pipe fittings and the pipe is melted and formed after cooling. Electrofusion connection is easy to operate, especially suitable for on-site construction, which can ensure the reliability of the connection.

3, flange connection: When the PE pipe needs to be connected with pipes or equipment of other materials, flange connection is a good choice. Through flanges, bolts and other accessories, the PE pipe is fixedly connected with other parts, which is firmly connected in this way, easy to disassemble and maintain, and is suitable for a variety of complex engineering scenarios.

Hubei AD Building Materials Co., Ltd., as a professional PE pipe manufacturer, not only provides high-quality PE pipe products, but also continuously optimizes the connection technology to provide users with professional and efficient connection solutions to meet the needs of different projects.